Purpose of a Grease Interceptor.

The main purpose of a grease interceptor is to catch and collect fats, oils, grease, and other food related solids and particles from a commercially used kitchen. As waste and water flow from the kitchen’s plumbing (e.g. 3-compartment sinks, prep sinks, mop sinks, dishwashers, floor drains, etc.) into a grease interceptor, the fats, oils, grease, and food particles within the waste-water is “intercepted” or filtered out, and thus collect into a large underground holding tank. Once the grease interceptor “holding tank” reaches maximum capacity for fats, oils, and grease (FOGs), a certified grease trap cleaning company will need to be called in order to service the grease interceptor. Failure to service a grease interceptor on a routine and timely basis can result in complete back-up of the kitchen’s entire plumbing system.

Design of a Grease Interceptor.

Grease interceptors generally are designed in two different types: 1) a hydromechanical grease interceptor (HGI) and 2) a gravity grease interceptor (GGI).

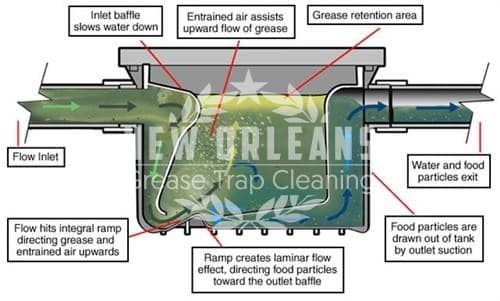

A Hydromechanical Grease Interceptor (HGI) is your basic grease trap. These are usually prefabricated steel manufactured units, and are normally located indoors at a centralized location, and are in close proximity to plumbing fixtures within a commercial kitchen. They are relatively small and compact in size, and normally utilize a hydraulic flow action, internal baffling, air entrainment, and a difference in specific gravity between water and fats, oils, and grease (FOG) for separation purposes.

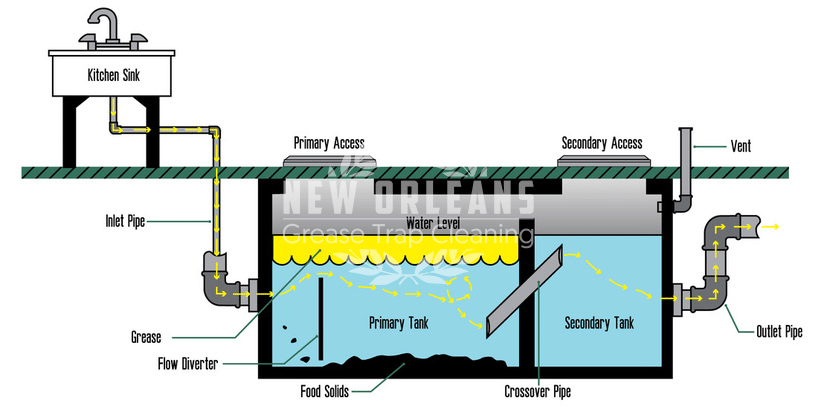

A Gravity Grease Interceptor (GGI) is engineered, prefabricated, and / or field-formed concrete constructed units that are typically located in the ground due to their large size and receive FOG discharge waste from all required fixtures within a kitchen’s plumbing system. Gravity grease interceptors use gravity flow and retention time as the primary means of separating fats, oils, and grease from the plumbing system’s waste stream prior to it entering the city sewer system’s municipal drainage system.

Service and Maintenance Cycle.

The service and maintenance cycle for a grease trap or grease interceptor can vary based upon several factors such as capacity, food type, restaurant or kitchen volume, and mandated ordinances. Generally speaking, most grease interceptors must be serviced at least every 90 days or at 20% discharge into the city sanitary sewer system.

For New Orleans area facility owners in need of grease trap or grease interceptor routine maintenance, please give us a call!

New Orleans Grease Trap Cleaning and Cooking Oil Recycling

New Orleans, LA 70115

United States (US)

Phone: (504)919-6699

Email: mike@neworleansgreasetrapcleaning.com

Price range: $125-$525

New Orleans Grease Trap Cleaning and Cooking Oil Recycling offers fairly priced grease trap and in-kitchen grease interceptor cleaning and used cooking oil recycling services to customers throughout Southeast Louisiana including New Orleans, Metairie, Kenner, the West Bank, the North Shore, LaPlace, Hammond, Raceland, Thibodaux, and Houma.